Save money and reduce down time with our 24/7, coast-to-coast spindle taper regrinding services across the U.S. and Mexico *

Learn More GET A QUOTEIf your machine is experiencing any of these problems the cause could be the taper seat

Checking The Health of Your Spindle Taper

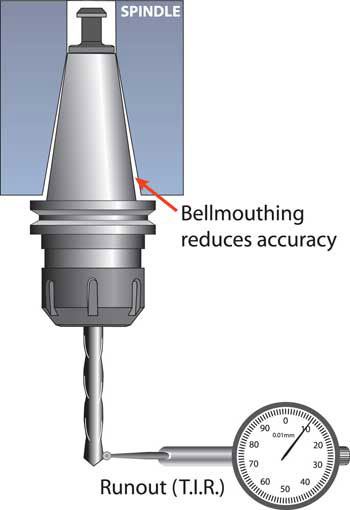

Bell Mouth Effect on Spindle

Bell Mouth condition is typical of tooling seat wear. Many times the wear may be concentric to the spindle bearings, so when checking for spindle run out with an indicator, the condition cannot be detected. However, when the machine is working and pressure of cutting applied, the tool holder unseats, causing the problems associated with a bad spindle taper seat.

Crash or Wreck

Broken cutters, retention knobs, and drawbars could be the result of pre-existing taper damage. As the power is transmitted through the taper seat, a poor fitting taper may let go. Wear on the keys in the face of the spindle may be evidence the taper is not holding.

Dirt

Dirt & chips find their way between the tool and spindle. Automatic tool changers may be equipped with air shop cleaners, but when you add coolant to the mix they become less reliable.

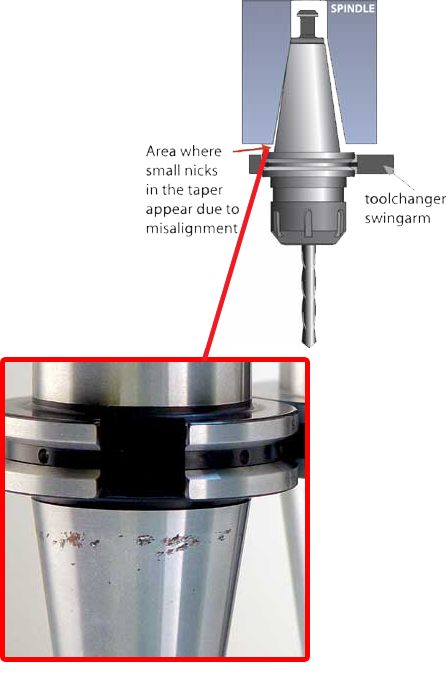

Automatic Tool Changers

ATC misalignment may cause tool holders to drag on one side of the seat every time a tool is put in and taken out causing wear on one side of the seat.

Manual Tool Changes

Heavy tools may cause the operator to bump the end of the tool against the taper seat, creating dents and raised areas around them. Look for dented or pitted surface of taper seat.

Spindle Bell Mouth Repair

A worn spindle can cause run out issues that affect tool holder accuracy and reduce cutting quality and productivity. This is a condition known as bell mouthing. If tool holder issues can be eliminated by bench checking T.I.R., then the source of the problem is often a worn out spindle mouth. A trained professional will be required to check and repair bell mouthing.

Save Your Cutting Tools From Premature Wearing

A worn out tool holder will not provide good accuracy and will quickly wear out your cutting tools. Worn tooling can also cause poor surface finish, and may even damage your spindle.

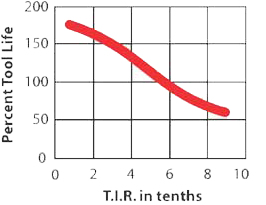

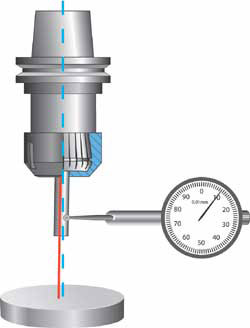

T.I.R. (total indicator run out) is the measurement of axial deflection of the cutting tool in the tool holder assembly. Technic’s tool holders are manufactured to minimize run out and extend cutting tool life. You lose 10% of cutting tool life for every “tenth” (0.0001″) of run out.

Taper Wear/Fretting

Check the taper for signs of wear or damage where it contacts the spindle mouth. Any problems with the taper will have a direct effect on machining accuracy. If there are any imperfections on the taper, the tool holder should not be used.

If noticeable marking is evident on the taper (see photo next page) a condition called fretting may be occurring. Fretting happens when two steel parts (holder and spindle mouth) are rubbing against one another. Fretting is caused by imperfect mating between tool holder taper and spindle, creating vibration and heat which develops the fretting. It is visible as small copper colored pits or marks on the taper. This is evidence that the tool holder is becoming worn. Fretting is easily mistaken for rust, but it is not. Once noticeable fretting develops the tool holder should be replaced. New tool holders that quickly develop fretting, or tool holders that stick in the spindle, may indicate a spindle that needs to be reground.

A worn taper causes an out-of-round condition when the holder is inserted into the spindle. This is called “run out”. Run out causes premature tool wear and excessive vibration during operation. This vibration can cause poor surface finish which may require additional operations to correct. Vibration can also cause heat build-up in the spindle and damage spindle bearings.